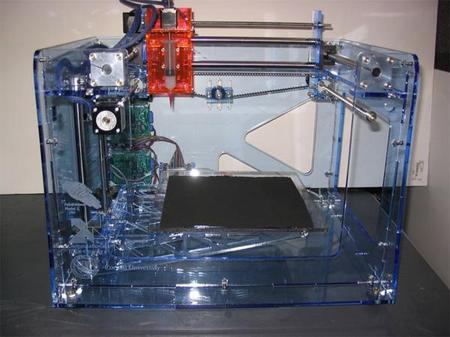

| Open Source Desktop Fabricator | 2007-01-12 00:15 3 comments |

by Flemming Funch by Flemming FunchNew Scientist: A cheap self-assembly device capable of fabricating 3D objects has been developed by US researchers. They hope the machine could kick start a revolution in home fabrication – or "rapid prototyping" – just as early computer kits sparked an explosion in home computing.Very cool. Fab@Home is the main page for the project. They hope to spark something like the revolution that happened when the first home computer kit, the Altair 8800, was made available in 1975. It didn't really do much, but thousands of people started tinkering with it and finding useful things to do with it, and devices to add to it. So, if lots of hobbyists have a DIY fabricator at home, the same thing might happen. Certainly they would at least want to share the blueprints for stuff one could build with it. But most likely they'd also help make it better. Like, somebody has already figured out how to print chocholate bars with it. |